Image credit: DGIST (Daegu Gyeongbuk Institute of Science and Technology)

The research group of Prof. Jong-Sung Yu from the Department of Energy Science and Engineering at DGIST has developed a technique to prepare a porous silica interlayer by loading sulfur, an active material, into silica. This new approach is expected to hold the key to the development and commercialization of next-generation lithium-sulfur batteries, where energy density and stability are critical.

With the recent increase in demand for large-capacity energy storage devices, research into high-energy, low-cost next-generation secondary batteries that can replace lithium-ion batteries is being actively conducted. The energy density of lithium-sulfur batteries using sulfur as the cathode material is several times higher than that of conventional lithium-ion batteries using expensive rare earth elements as the cathode material. Therefore, it is expected that sulfur-based batteries will be more suitable for high-energy devices such as electric vehicles and drones. In addition, research on lithium-sulfur batteries is also widespread because sulfur is inexpensive, abundant, and nontoxic.

On the other hand, sulfur is an active element that generates electricity, and its electrical conductivity is low, and the polysulfides generated during the charging and discharging process of the battery diffuse to the negative electrode of the battery, resulting in the loss of sulfur and lithium in the reaction. Therefore, the capacity and lifespan of the battery are significantly degraded. This problem is ameliorated by inserting a new layer between the sulfur electrode and the separator (middle), which can absorb polysulfides and prevent diffusion.

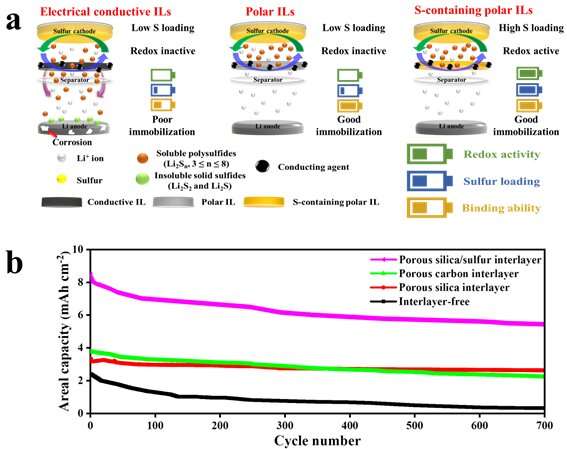

Conductive carbon is currently used as an interlayer technology to improve the capacity and lifetime of lithium-sulfur batteries, which imparts conductivity to the sulfur electrode. However, due to the low affinity of sulfur for polar lithium polysulfides, the diffusion of sulfur cannot be prevented. On the other hand, if polar oxides are used as the interlayer material, the loss of sulfur is suppressed due to the strong interaction with lithium polysulfides. However, due to the low conductivity of sulfur, the utilization rate of sulfur is low. In addition, various interlayer materials previously studied are not ideal due to their low thickness and redox activity, which cannot achieve the energy density and cycle life required for commercialization.

To address these shortcomings, the research team first realized a new redox-active porous silica/sulfur interlayer by adding sulfur to the silica after synthesizing the plate-like porous silica. They predict that the capacity and lifetime efficiency of lithium-sulfur batteries will be maximized due to the sulfur-induced increase in capacity per cell area, as additional sulfur is loaded in the interlayer, which can also serve as an efficient lithium polysulfide adsorption site.

To investigate this theory, a silicon dioxide/sulfur interlayer was applied to a lithium-sulfur battery, which was then charged and discharged 700 times. As a result, the porous silica/sulfur interlayer achieved much higher long-term stability than conventional porous carbon/sulfur interlayers after 700 charge/discharge cycles.In particular, the battery exhibits high capacity and durable, long-lasting properties even at a high sulfur content of 10 mg/cm2 and low electrolyte: sulfur (E/S) concentration of 4. Therefore, it is close to practical application.

Professor Jong-Sung Yu said, “Our study found for the first time that sulfur can be loaded into the pores of porous silica materials as an interlayer material for lithium-sulfur batteries, improving their capacity and lifetime.” He added: “This result It is a new milestone in the development of next-generation high-energy, long-life lithium-sulfur batteries.”

This research was conducted in collaboration with Ph.D. Amine Khalil’s team at Argonne National Laboratory (ANL). PhD. Byung-Jun Lee, Ph.D. Under the supervision of Prof. Jong-Sung Yu from the Department of Energy and Science and Engineering at DGIST, he is the first author.The study was published online Aug. 8 in Nature Communications.

Next-generation lithium-sulfur batteries address sulfur loss

Byong-June Lee et al., developed high-energy non-aqueous lithium-sulfur batteries through a redox-active interlayer strategy, Nature Communications (2022). DOI: 10.1038/s41467-022-31943-8

Provided by DGIST (Daegu Gyeongbuk University of Science and Technology)

Citation: A turning point in technology in the field of lithium-sulfur batteries (September 27, 2022) Retrieved on September 27, 2022 from https://techxplore.com/news/2022-09-lithium-sulfur-battery-field-technology.html

This document is protected by copyright. Except for any fair dealing for private study or research purposes, no part may be reproduced without written permission. The content is for reference only.